MS 20002 – This specification replaced specification NAS 143 in 1954 and includes washers made from 4130 Chrome Molybdenum Steel. They are available with both flat and a 45° countersink, heat treated and plated. They are primarily for use with 160, 000 psi bolts.

MS 20002 – This specification replaced specification NAS 143 in 1954 and includes washers made from 4130 Chrome Molybdenum Steel. They are available with both flat and a 45° countersink, heat treated and plated. They are primarily for use with 160, 000 psi bolts.

MS 17811 – these are case hardened 1020 steel thrust washers, available in 23 sizes from WCL. They are designed primarily for supporting end load thrust bearings. Call for information.

MS 21206 – Washers available in this series are both plain and countersunk, made from Alloy Steel, heat treated and plated. They are normally used with MS21134 and MA 21297 bolts and with MS 21133 and MS 21804 nuts.

MS 9320 – Washers are made from AMS 6350 Corrosion Resistant Steel with Diffused Cadmium Nickel Plate.

NAS 1587 – Available both flat and with a 45° countersunk, these washers are made from Corrosive Resistant Steel with 75, 000 psi, UTS min.

10910174 Ordnance Washers – This specification covers 46 various sizes of washers made from Alloy Steel, heat treated and Cadmium Plated for military use. All are stocked by WCL. These washers also account for many commercial applications.

Available but not listed – The following Double Countersunk 45° MS Series washers are available from WCL, but space limitations prevent their listing: MS 9482, MS 9768, MS 14155, and MS 14177. Also available but not shown are countersunk washers with 100° angles and other special configurations.

Many other sizes of unlisted hardened washers are also in stock. If not listed here, call WCL to check availability and get samples and a quotation.

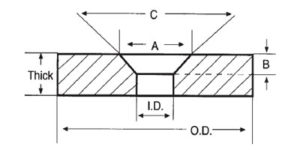

| Screw/Bolt Size | I.D. | O.D. | Thickness | CTSK P/N |

A CTSK I.D. |

B CTSK Depth |

C CTSK Degree |

Reference Part Numbers |

Steel Plated Dash P/N | Stainless Steel Dash P/N |

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 0.093 | 0.187 | 0.019 | 2W1G-6-6- | 19 | |||||

| 3 | 0.119 | 0.25 | 0.031 | MS9320 | 04 | |||||

| 4 | 0.124 | 0.245 | 0.04 | ALLOY 4 | X | |||||

| 4 | 0.135 | 0.312 | 0.031 | MS9320 | 05 | |||||

| 5 | 0.15 | 0.312 | 0.043 | MS9320 | 06 | |||||

| 6 | 0.159 | 0.375 | 0.043 | MS9320 | 07 | |||||

| 8 | 0.184 | 0.375 | 0.05 | MS9320 | 08 | |||||

| 10 | 0.193 | 0.367 | 0.062 | C3 | 0.285 | 0.063 | 45° | MS21206 | 3 | |

| 10 | 0.193 | 0.377 | 0.062 | MS21299 | 3 | |||||

| 10 | 0.195 | 0.469 | 0.032 | NAS1587 | 3 | |||||

| 10 | 0.213 | 0.438 | 0.062 | MS9320 | 09 | |||||

| 1/4 | 0.253 | 0.465 | 0.062 | C4 | 0.345 | 0.063 | 45° | MS21206 | 4 | |

| 1/4 | 0.253 | 0.481 | 0.062 | MS21299 | 4 | |||||

| 1/4 | 0.255 | 0.485 | 0.057 | BACW10BP | 4P | |||||

| 1/4 | 0.255 | 0.531 | 0.062 | C4 | 0.339 | 0.078 | 45° | MS20002 | 4 | |

| 1/4 | 0.256 | 0.531 | 0.062 | 4C | 0.339 | 0.078 | 45° | NAS1587 | 4 | |

| 1/4 | 0.265 | 0.5 | 0.065 | NAS1149 | G0463P | |||||

| 1/4 | 0.276 | 0.5 | 0.062 | MS9320 | 10 | |||||

| 1/4 | 0.281 | 0.5 | 0.089 | 10910174 | 1 | |||||

| 1/4 | 0.281 | 0.625 | 0.089 | 10910174 | 34 | |||||

| 1/4 | 0.281 | 1 | 0.089 | 10910174 | 20 | |||||

| 5/16 | 0.316 | 0.568 | 0.062 | C5 | 0.407 | 0.063 | MS21206 | 5 | ||

| 5/16 | 0.319 | 0.593 | 0.062 | C5 | 0.401 | 0.078 | 45° | MS20002 | 5 | |

| 5/16 | 0.319 | 0.593 | 0.062 | 5C | 0.401 | 0.078 | 45° | NAS1587 | 5 | |

| 5/16 | 0.328 | 0.562 | 0.063 | NAS1149 | G0563P | |||||

| 5/16 | 0.338 | 0.625 | 0.062 | MS9320 | 11 | |||||

| 5/16 | 0.343 | 0.625 | 0.062 | 10910174 | 17 | |||||

| 5/16 | 0.343 | 0.625 | 0.104 | 10910174 | ||||||

| 5/16 | 0.343 | 0.875 | 0.119 | 10910174 | 19 | |||||

| 3/8 | 0.378 | 0.674 | 0.062 | C6 | 0.502 | 0.078 | 45° | MS21206 | 6 | |

| 3/8 | 0.383 | 0.687 | 0.062 | C6 | 0.489 | 0.078 | 45° | MS20002 | 6 | |

| 3/8 | 0.383 | 0.687 | 0.062 | 6C | 0.489 | 0.078 | 45° | NAS1587 | 6 | |

| 3/8 | 0.39 | 0.625 | 0.063 | NAS1149 | G0663P | |||||

| 3/8 | 0.39 | 0.937 | 0.045 | S6135-64028- | 3 | |||||

| 3/8 | 0.401 | 0.75 | 0.078 | MS9320 | 12 | |||||

| 3/8 | 0.406 | 0.7 | 0.158 | 10910174 | 33 | |||||

| 3/8 | 0.406 | 0.75 | 0.119 | 10910174 | 3 | |||||

| 3/8 | 0.406 | 0.875 | 0.134 | 10910174 | 22 | |||||

| 3/8 | 0.406 | 1.125 | 0.199 | 10910174 | 16 | |||||

| 7/16 | 0.438 | 0.922 | 0.065 | ASTM A-325 | X | |||||

| 7/16 | 0.441 | 0.778 | 0.062 | C7 | 0.564 | 0.078 | 45° | MS21206 | 7 | |

| 7/16 | 0.446 | 0.781 | 0.062 | C7 | 0.55 | 0.078 | 45° | MS20002 | 7 | |

| 7/16 | 0.446 | 0.781 | 0.062 | 7C | 0.55 | 0.078 | 45° | NAS1587 | 7 | |

| 7/16 | 0.453 | 0.75 | 0.063 | 7C | 0.55 | 0.078 | 45° | NAS1149 | G07636P | |

| 7/16 | 0.463 | 0.875 | 0.094 | MS9320 | 13 | |||||

| 7/16 | 0.468 | 0.75 | 0.119 | 10910174 | 26 | |||||

| 7/16 | 0.468 | 0.875 | 0.119 | 10910174 | 4 | |||||

| 7/16 | 0.468 | 0.875 | 0.25 | 10910174 | 35 | |||||

| 7/16 | 0.482 | 0.905 | 0.29 | 12376084 | ||||||

| 1/2 | 0.501 | 0.888 | 0.062 | 4130 | X | |||||

| 1/2 | 0.503 | 0.893 | 0.062 | C8 | 0.627 | 0.078 | 45° | MS21206 | 8 | |

| 1/2 | 0.509 | 0.875 | 0.062 | C8 | 0.612 | 0.078 | 45° | MS20002 | 8 | |

| 1/2 | 0.509 | 0.875 | 0.062 | C8 | 0.612 | 0.078 | 45° | NAS1587 | 8 | |

| 1/2 | 0.515 | 0.875 | 0.063 | NAS1149 | G0863P | |||||

| 1/2 | 0.516 | 0.875 | 0.125 | 11678182 | ||||||

| 1/2 | 0.526 | 1 | 0.109 | MS9320 | 14 | |||||

| 1/2 | 0.531 | 0.875 | 0.06 | 10910174 | 37 | |||||

| 1/2 | 0.531 | 0.875 | 0.089 | 10910174 | 30 | |||||

| 1/2 | 0.531 | 0.875 | 0.127 | 10910174 | 43 | |||||

| 1/2 | 0.531 | 1 | 0.134 | 10910174 | 5 | |||||

| 1/2 | 0.531 | 1.5 | 0.06 | 10910174 | 40 | |||||

| 1/2 | 0.531 | 2 | 0.209 | 10910174 | 28 | |||||

| 1/2 | 0.562 | 1.5 | 0.16 | 9152386 | X | |||||

| 9/16 | 0.566 | 1.004 | 0.062 | C9 | 0.689 | 0.078 | 45° | NS21206 | 9 | |

| 9/16 | 0.57 | 0.968 | 0.062 | C9 | 0.677 | 0.078 | 45° | MS20002 | 9 | |

| 9/16 | 0.57 | 0.968 | 0.062 | C9 | 0.677 | 0.078 | 45° | NAS1587 | 9 | |

| 9/16 | 0.578 | 1.062 | 0.063 | NAS1149 | G0963P | |||||

| 9/16 | 0.588 | 1.125 | 0.125 | MS9320 | 15 | |||||

| 9/16 | 0.594 | 1.125 | 0.164 | 10910174 | 6 | |||||

| 5/8 | 0.626 | 1.182 | 0.062 | MS21299 | 10 | |||||

| 5/8 | 0.629 | 1.12 | 0.062 | C10 | 0.783 | 0.078 | 45° | MS21206 | 10 | |

| 5/8 | 0.638 | 1.062 | 0.062 | C10 | 0.775 | 0.078 | 45° | MS20002 | 10 | |

| 5/8 | 0.638 | 1.062 | 0.062 | C10 | 0.775 | 0.078 | 45° | NAS1587 | 10 | |

| 5/8 | 0.64 | 1.188 | 0.063 | C10 | 0.775 | 0.078 | 45° | NAS1587 | G1063P | |

| 5/8 | 0.651 | 1.25 | 0.141 | MS9320 | 16 | |||||

| 5/8 | 0.656 | 1 | 0.119 | 10910174 | 31 | |||||

| 5/8 | 0.656 | 1 | 0.25 | 10910174 | 21 | |||||

| 5/8 | 0.656 | 1.25 | 0.164 | 10910174 | 7 | |||||

| 5/8 | 0.656 | 1.25 | 0.25 | 10910174 | 18 | |||||

| 5/8 | 0.656 | 1.5 | 0.089 | 10910174 | 44 | |||||

| 5/8 | 0.656 | 1.75 | 0.179 | 10941915 | 7 | |||||

| 5/8 | 0.656 | 1.75 | 0.25 | 10910174 | 38 | |||||

| 5/8 | 0.656 | 2.5 | 0.125 | 10910174 | 25 | |||||

| 5/8 | 0.687 | 1.312 | 0.093 | A-325 | X | |||||

| 3/4 | 0.754 | 1.345 | 0.062 | C12 | 0.908 | 0.078 | 45° | MS21206 | X | |

| 3/4 | 0.765 | 1.25 | 0.062 | C12 | 0.9 | 0.078 | 45° | MS20002 | 12 | |

| 3/4 | 0.765 | 1.25 | 0.062 | C12 | 0.9 | 0.078 | 45° | NAS1587 | 12 | |

| 3/4 | 0.765 | 1.312 | 0.09 | NAS1149 | G1290P | |||||

| 3/4 | 0.765 | 1.38 | 0.125 | 4130 | X | |||||

| 3/4 | 0.776 | 1.5 | 0.172 | MS9320 | 17 | |||||

| 3/4 | 0.78 | 1.5 | 0.062 | 10910174 | 41 | |||||

| 3/4 | 0.781 | 1.5 | 0.093 | 10910174 | 24 | |||||

| 3/4 | 0.781 | 1.5 | 0.125 | 10910174 | 42 | |||||

| 3/4 | 0.781 | 1.687 | 0.25 | 10910174 | 23 | |||||

| 3/4 | 0.812 | 2 | 0.179 | 10910174 | 15 | |||||

| 3/4 | 0.812 | 2 | 0.194 | 10910174 | 8 | |||||

| 7/8 | 0.879 | 1.567 | 0.062 | C14 | 1.033 | 0.078 | 45° | MS21206 | 14 | |

| 7/8 | 0.877 | 2.25 | 0.187 | MS17811 | 18 | |||||

| 7/8 | 0.888 | 1.437 | 0.062 | C14 | 1.025 | 0.078 | 45° | MS20002 | 14 | |

| 7/8 | 0.888 | 1.437 | 0.062 | C14 | 1.025 | 0.078 | 45° | NAS1587 | 14 | |

| 7/8 | 0.89 | 1.5 | 0.09 | NAS1149 | G1490P | |||||

| 7/8 | 0.901 | 1.75 | 0.203 | MS9320 | 18 | |||||

| 7/8 | 0.938 | 1.781 | 0.194 | 10910174 | 9 | |||||

| 1″ | 1.015 | 1.625 | 0.062 | C16 | 1.15 | 0.078 | 45° | MS2002 | 16 | |

| 1″ | 1.015 | 1.625 | 0.062 | C16 | 1.15 | 0.078 | 45° | NAS1587 | 16 | |

| 1″ | 1.015 | 1.75 | 0.09 | NAS1149 | G1690P | |||||

| 1″ | 1.02 | 1.72 | 0.06 | 10910174 | 29 | |||||

| 1″ | 1.026 | 2 | 0.234 | MS9320 | 19 | |||||

| 1″ | 1.062 | 2.031 | 0.209 | 10910174 | 10 | |||||

| 1-1/16 | 1.078 | 1.812 | 0.09 | NAS1149 | G1890P | |||||

| 1-1/8 | 1.145 | 1.875 | 0.062 | C18 | 1.275 | 0.078 | 45° | MS20002 | 18 | |

| 1-1/8 | 1.145 | 1.875 | 0.062 | C18 | 1.275 | 0.078 | 45° | NAS1587 | 18 | |

| 1-1/4 | 1.265 | 2 | 0.09 | NAS1149 | G2090P | |||||

| 1-1/4 | 1.269 | 2.125 | 0.062 | C20 | 1.437 | 0.094 | 45° | MS20002 | 20 | |

| 1-1/4 | 1.269 | 2.125 | 0.094 | C20 | 1.437 | 0.094 | 45° | NAS1587 | 20 | |

| 1-5/16 | 1.328 | 2.062 | 0.09 | NAS1149 | G2190P | |||||

| 1-3/8 | 1.395 | 2.313 | 0.062 | C22 | 1.562 | 0.094 | 45° | MS20002 | 22 | |

| 1-1/2 | 1.515 | 2.5 | 0.062 | C24 | 1.687 | 0.094 | 45° | MS20002 | 24 |

WCL Part Numbers – reference part example: 10910174-42 above is WCL part: FW-0781-1500-125-ST4-CD2

Use Reference and/or MilSpec part numbers when needed. Specify hardness requirements as needed. See Plating And Material Specifications for a complete

listing of materials, finishes and applicable WCL codes.